Engineering Precision in the Vascular Medical Device Sector

In the vascular device domain, engineering precision is not just a differentiator—it’s a regulatory and clinical requirement. As device architectures become more complex and miniaturized, design engineers are being tasked with delivering micron level accuracy, multi-material integration, and long-term biocompatibility—all while maintaining cost-efficiency and compliance.

Paragon Medical is a market leader in delivering optimal solutions for the medical device industry, including the vascular sector. More than 40 years of expertise spans across various areas such as product design and development, precision engineering, pre-production to commercialized manufacturing, supply chain management, and quality assurance.

Design and Development Challenges in Vascular Devices

Medical design engineers face a unique set of constraints:

- Regulatory Complexity: ISO 13485 and FDA 21 CFR Part 820 demand robust design controls, traceability, and risk management. Design Verification and Validation (V&V) activities must be tightly aligned with clinical use cases and failure mode analysis (FMEA).

- Miniaturization and Integration: Devices such as vascular imaging catheters and closure clips require integration of optics, sensors, and actuation mechanisms within diameters smaller than 2mm.

- Material-Process Interactions: Nitinol, cobalt-chrome, and bioabsorbable polymers each present unique challenges in terms of laser processing, fatigue resistance, and surface passivation.

- Mechanical and Fluidic Performance: Engineers must optimize for radial strength, flexibility, and hemodynamic compatibility—often using FEA and CFD simulations to validate performance under pulsatile flow conditions.

Engineering Solutions: From Concept to Commercialization

To address these multifaceted challenges, Paragon Medical offers a comprehensive suite of services and technical capabilities designed specifically for the vascular sector. The following highlights some of the key capabilities and specialized services Paragon Medical provides to advance innovation in vascular medical devices:

- Precision Laser Processing for Implants and Delivery Systems.

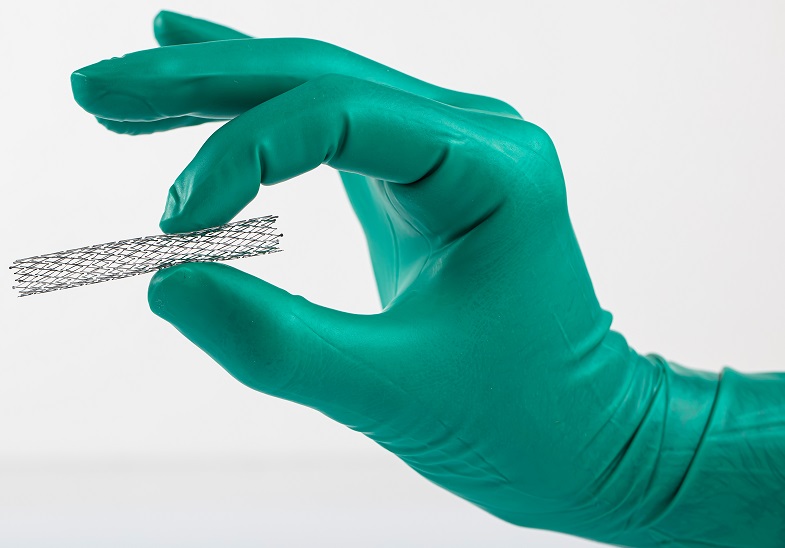

Laser micromachining is essential for fabricating vascular stents and scaffolds with strut widths as low as 50–100 µm and tolerances within ±5 µm.

Key process parameters include:

- Pulse Duration: Femtosecond and picosecond lasers reduce HAZ (heat-affected zone) and recast layer formation.

- Wavelength: 532 nm and 1064 nm are commonly used for metals; UV lasers (355 nm) are preferred for polymers.

- Assist Gases: Argon or nitrogen is used to prevent oxidation during cutting of Nitinol and stainless steel.

Post-processing steps such as electropolishing and passivation are critical to remove burrs, reduce surface roughness (Ra < 0.2 µm), and enhance corrosion resistance.

- Polymer Laser Ablation and Multi-Lumen Catheter Integration

Laser ablation enables precise feature creation in thermoplastics like Pebax, PTFE, and polyimide. Applications include:

- Micro-hole drilling for drug elution or pressure sensing (diameters < 100 µm).

- Surface texturing to improve adhesive bonding or electrode deposition.

- Multi-lumen fusion for integrating fluidic, electrical, and optical channels in a single catheter shaft.

Thermal management and beam shaping are essential to avoid delamination or deformation of thin-walled tubing (< 0.5 mm wall thickness).

- Custom Interconnects for Imaging and Sensing Systems

High-density interconnects (HDIs) are enabling real-time intravascular imaging and electrophysiological mapping. Engineering considerations include:

- Micro-coaxial cable assemblies with diameters < 0.3 mm for signal integrity.

- Laser welding of micro-connectors to ensure hermetic sealing and mechanical robustness.

- Shielding and EMI mitigation for high-frequency data transmission (e.g., OCT or IVUS systems).

Design teams often use impedance-controlled PCB flex circuits and strain relief modeling to ensure durability under repeated flexion.

- Cross-Functional Engineering and PLM Integration

PLM systems support:

- Concurrent engineering across mechanical, electrical, and software domains.

- Design history file (DHF) traceability for regulatory audits.

- Human factors integration using usability engineering files (UEFs) and simulated use testing.

This enables faster design iterations and smoother transitions from R&D to manufacturing transfer.

- Sector-Specific Engineering Capabilities

Leveraging deep expertise and advanced engineering, Paragon Medical delivers innovative solutions tailored to the unique demands of each medical sector.

|

Medical Sector

|

Engineering Focus

|

Technical Capabilities

|

|

Neurovascular

|

Micro-scale catheter components

|

Laser ablation, fine wire cabling

|

|

Peripheral Vascular

|

Durable, flexible implants & delivery systems

|

Precision laser tube processing & welding of catheter assemblies

|

|

Structural Heart

|

High-strength, fatigue-resistant implants

|

Laser-cutting, electropolishing

|

|

Electrophysiology

|

Signal fidelity, reliability & innovative solutions

|

Custom HD data connectors, automated electrode welding, fine wire ablation & braided cables

|

|

Neuromodulation

|

Long-term implantable leads

|

Multi-lumen tubing ablation, fine wire ablation, silicone molding, wire termination

|

- Materials Engineering and Biocompatibility

Material selection in vascular device design is driven by a combination of mechanical performance, chemical stability, and biological compatibility. These factors are evaluated early in the design process to ensure manufacturability, regulatory compliance, and long-term clinical performance. Key materials include:

- Nitinol: Known for its superelasticity and shape memory properties, Nitinol is widely used in self-expanding stents and frames. Engineering considerations include oxide layer control, fatigue resistance (10⁷–10⁸ cycles), and nickel ion leach testing per ISO 10993-18.

- Titanium: Valued for its high strength-to-weight ratio, corrosion resistance, and excellent biocompatibility. Titanium is often used in implantable housings, connectors, and structural components. Surface treatments such as anodization and grit blasting are applied to enhance osseointegration and bonding.

- Cobalt-Chrome Alloys: These alloys offer high tensile strength, wear resistance, and radiopacity, making them ideal for balloon-expandable stents and load-bearing implants. Laser cutting and electropolishing are used to achieve precise geometries and smooth surfaces.

- Magnesium: As a bioresorbable metal, magnesium alloys are gaining traction for temporary scaffolds and drug-eluting platforms. Their degradation rate must be carefully controlled through alloy composition and surface coatings to match tissue healing timelines.

- Bioabsorbable Polymers: Materials such as PLLA (poly-L-lactic acid) and PCL (polycaprolactone) are used in resorbable scaffolds and drug delivery systems. These

polymers require degradation modeling, mechanical property tuning, and in vitro/in vivo correlation studies.

Surface Engineering: Functional coatings are applied to enhance device performance and biocompatibility. Techniques include:

- Plasma treatment for surface activation

- Dip or spray coating for hydrophilic or drug-eluting layers

- Antimicrobial coatings to reduce infection risk

- Passivation to improve corrosion resistance, particularly for metallic implants

Conclusion: Engineering as a Strategic Enabler

For medical design engineers, the vascular device sector presents a unique convergence of challenges—mechanical, electrical, biological, and regulatory. Success depends on the ability to integrate advanced manufacturing techniques, materials science, and system-level design thinking.

Whether developing imaging catheters, vessel closure devices, or implantable scaffolds, precision engineering is the foundation of clinical performance and regulatory success.

With decades of experience and a commitment to innovation, Paragon Medical stands at the forefront of vascular device development, delivering precise, reliable solutions that advance patient care and set new industry standards.